Cost-Effective Prefabricated Steel Structure Warehouse Industrial Workshop Modular Design Customizable Layout Quick Assembly High-Strength Steel Frame Weatherproof Logistics Storage Manufacturing

| Specifications: |

| Main Steel Frame | H section steel beam and columns, painted or hot dip galvanizing, galvanized C section or steel pipe |

| Secondary Frame | Hot dip galvanized C purlin, steel bracing , tie bar , knee brace , edge cover etc. |

| Roof Panel | Steel sheet, Alum-Zinc sheet , Alumnium sheet, EPS sandwich panel,glass fiber sandwich panel,rock wool sandwich panel,and PU sandwich panel etc. |

| Wall Panel | Sandwich Panel or Corrugated Steel Sheet etc. |

| Tie Rod | Circular Steel Tube |

| Brace | Round Bar |

| Knee Brace | Angle Steel |

| Roof Gutter | Color Steel Sheet, Alum-zinc sheet, Gal. sheet, Stainless steel |

| | (1) Customized design is welcomed. We will quote for you promptly. |

| (2) In order to give you an exactly quotation and drawings,please let us know the length, width , eave height and local weather. |

The above is for reference only, the specific required material components according to customer needs. |

Technical Parameters

If you have drawings, welcome to share drawings with us, quoation will be done based your drawings. Our excellent design team will design the steel structure workshop warehouse for you. If you give the following information, we will give you an satisfactory drawing.

1. Location: where will be built? which country? which city?

2. Size: Length*width* Eave height

3. Wind load: max wind speed _____kn/m2, _____km/h, _____m/s

4. Snow load: max snow height _____kn/m2, _____mm, temperature range?

5. Anti-earthquake _____level

6. Brickwall needed or not: If yes, 1.2m high or 1.5m high? or other?

7. Thermal insulation: If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8. Door quantity & size _____units, _____(width)mm*_____(height)mm

9. Window quanity & size _____units, _____(width)mm*_____(height)mm

10. Crane needed or not: If yes, _____units, max lifting weight____tons, max lifting height _____m

Applications

Wide Range of Applications

Steel structure buildings are versatile and suitable for various industrial and commercial uses:

- Manufacturing Facilities: Automotive plants, machinery workshops, food processing plants.

- Warehouses & Logistics Centers: Distribution hubs, cold storage, bulk storage facilities.

- Aircraft Hangars: Requiring very large, clear-span areas.

- Power Stations & Substations

- Agricultural Buildings: Large barns, storage silos, and processing facilities.

- Retail Outlets & Superstores (Big-Box Stores)

The Construction Process

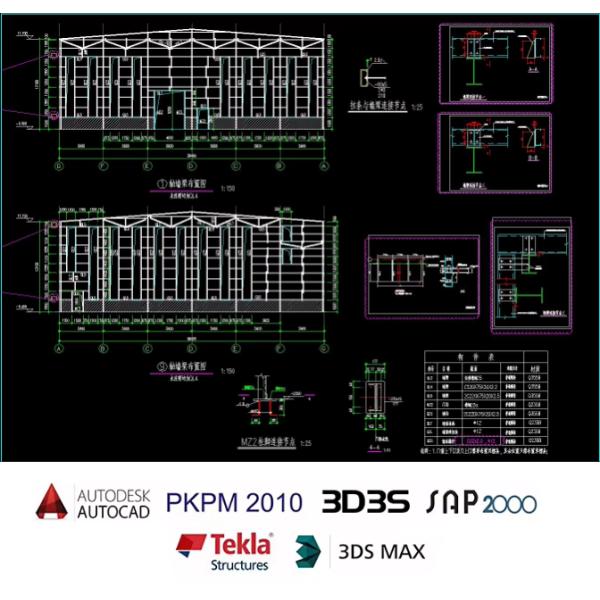

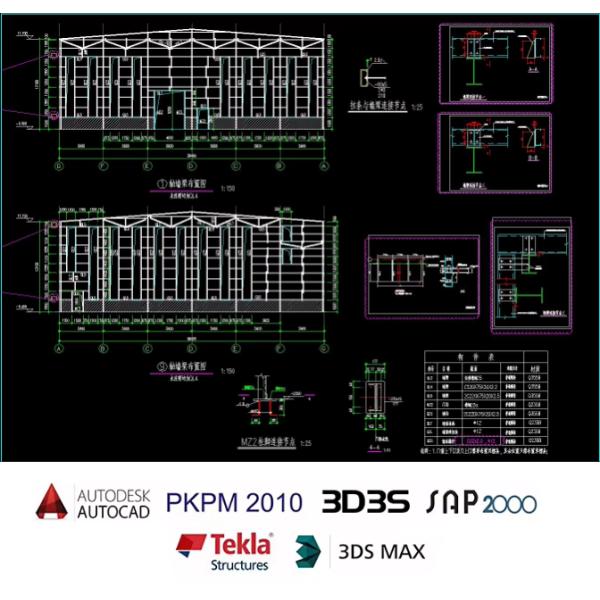

- Design & Engineering: Creating detailed architectural and structural drawings, including calculations for loads and connections.

- Fabrication: Cutting, welding, and drilling steel components in a controlled factory environment based on the design.

- Site Preparation & Foundation: Excavation and pouring of concrete foundations, often with embedded anchor bolts.

- Erection: Assembling the primary steel frame (columns, beams), followed by the secondary elements (purlins, girts).

- Enclosure: Installing the roof and wall cladding systems, along with insulation.

- Finishing: Adding doors, windows, ventilation systems, skylights, and interior finishes.

Packing and Shipping

Mode Of Despatch

1.Steel components are packaged with iron pallets at the factory with the codingnumber, which is convenient for customers to unload; small steel structures arebundled with iron wires and hung with tags.

2.Fasteners are packed in steel boxes.

3.The upper layer of the color-coated roof and wall panel is covered with plastic film,and the maintenance edge is wrapped with plastic film and labelled.

4.Container type:40ft HC,40ft OT,20ft GP

5.Mode of transportation: sea, air, inland transportation

Company Profile

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house.

Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world.

Baodu has a professional design team with more than 10 years' experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc.

Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

AFTER-SALE SERVICE

1.Sales - design - refinement - procurement - production - packaging - delivery -constructionafter-sales in one-stop service

2. 24 hour consultation service

3. Provide technical support: modeling and drawing design

4. Professional construction technicians can be dispatched for on-site guidance

5. Related products on behalf of procurement

6. Steel processing equipment is complete

7. Welding workers have 5-8 years of working experience with certificates, certificate rate of 95%.

8. Specialized quality inspection department: all processes have full quality inspection project

FAQ

1) Is your company a factory or trade company?

We are factory, so you can get the best price and competitive price.

2) What can you buy from us?

Steel structure, building materials, steel structure building system, poultry farm system, customized steel 24-hour one-stop service.

3) Do you offer guiding installation on site overseas for warehouse building?

Yes, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to supervise installation on site overseas. They have succeeded in more than 50 countries, such as Algeria, Ghana, Ethiopia, Nigeria, Philippines, Angola, Mauritius, Papua New Guinea, USA, Australia,Uganda, Netherlands etc.

4) What is your main market?

Guided by global field of vision, our products have been exported to 130 countries and regions with its good quality and good service, such as Asia, Europe,Oceania, Asia, Africa, North and South America, Latin America and other regions, achieving sustained and stable cooperation.

5) How to pack the products?

We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.